As the most common processing method of modern binding, Saddle Stitch is the primary choice for many printing companies to carry out paper seals after processing. Influenced by the market environment, the ride -up process is also changing rapidly. How to effectively improve the overall benefits of Saddle Stitch processing?

Horizon has helped many companies complete the perfect transformation from traditional riding to modern cyclical production models. What skills do it contain? Find the answer from Horizon's device.

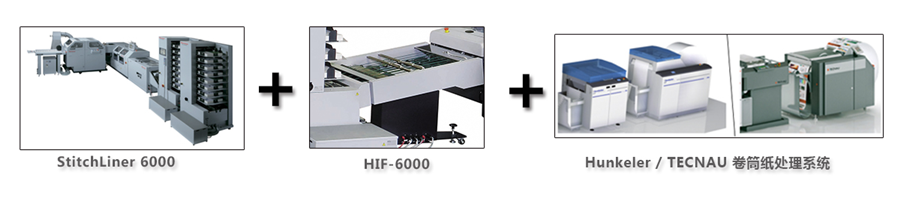

Stitchliner 6000

Different from the traditional Saddle Stitch device is that the StitchLiner 6000 first has enough advantages in performance. The production capacity of 6000 volumes per hour is destined to be a congenital advantage on the Saddle Stitch processing of the StitchLiner 6000 in the medium and short version of Saddle Stitch (the medium and short version of the short version of Saddle Stitch here).

In addition to its superior performance, StitchLiner 6000 also has its unique "money saving" technique in saving production costs. Where is the StitchLiner 6000 province? It can be summarized as three aspects:

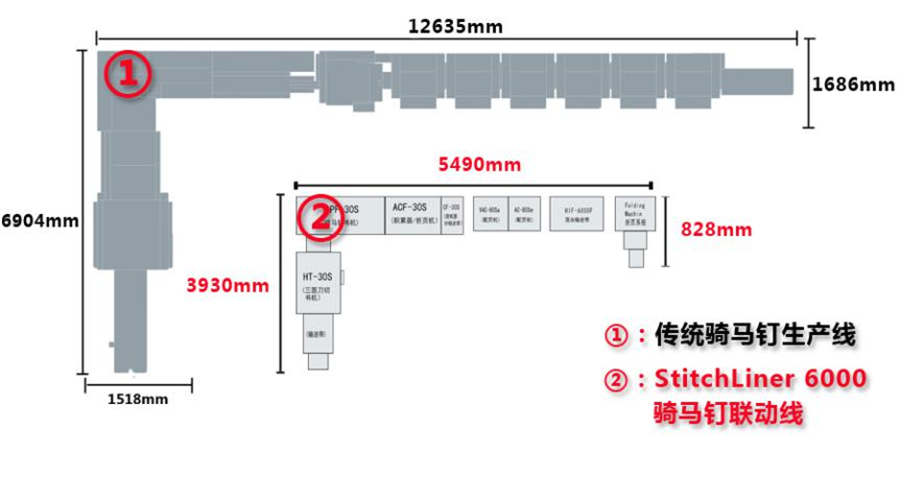

Save space

StitchLiner 6000 adopts the "L" structure, which greatly saves the area of occupying the production workshop. However, due to the smaller space occupying the space, the effective space becomes more indirect. The extra space can increase the production line and be used to configure other value -added projects.

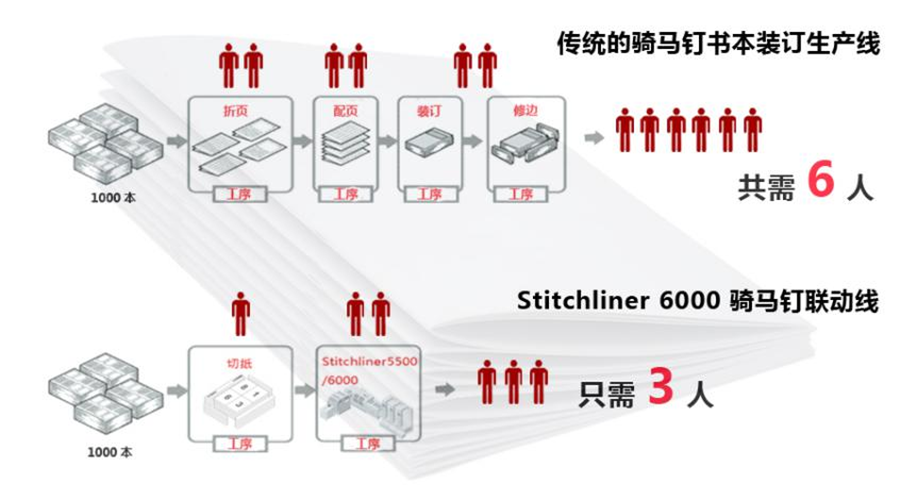

Manually

Traditional Saddle Stitch and StitchLiner 6000 manual configuration comparison chart (1,000 output as an example):

Traditional SADDLE Stitch: 2 people with a folding process+page distribution process 2 people+binding and edge processes 2 people need 6 people in total

StitchLiner 6000 horse riding nails: 1 person cutting process+operation StitchLiner 6000 2 people = only 3 people need 3 people

As can be seen from the above data, when the output is the same, the StitchLiner 6000 needs only 3 people to complete the entire production, and the artificial savings are 50%. If an employee's monthly salary is 5000 RMB. The three employees are 3x5000 = 15000 RMB. 12x15000 = 180,000 RMB in 12 months a year!

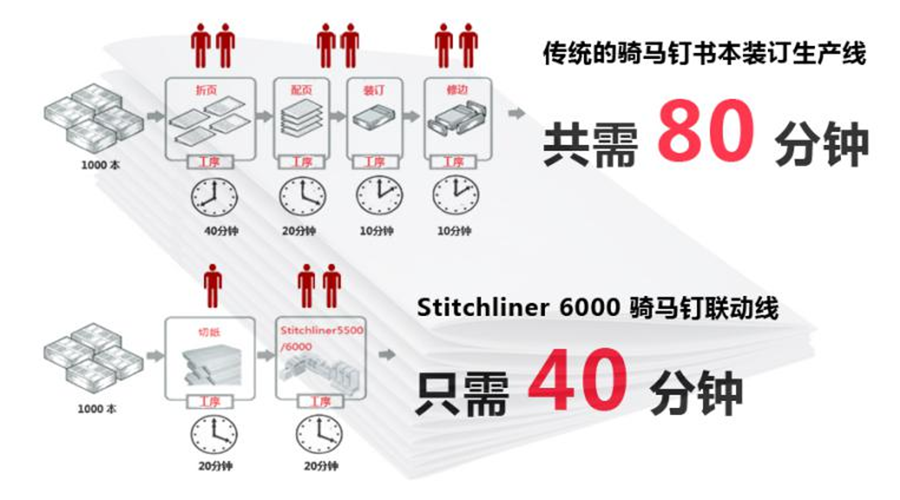

Save time

Traditional SADDLE Stitch and StitchLiner 6000 production time comparison (1,000 output as an example):

Traditional SADDLE Stitch: 40 minutes of the folding process+20 minutes of the pages+binding and edge process 20 minutes = a total of 80 minutes

StitchLiner 6000: 20 minutes of cutting paper+operation StitchLiner 600020 minutes = only 40 minutes

In the same output, only half of the original (80-40 = 40 minutes) is required. In the same case of working hours, the output of the StitchLiner 6000 can reach twice the traditional Saddle Stitch book binding production line!

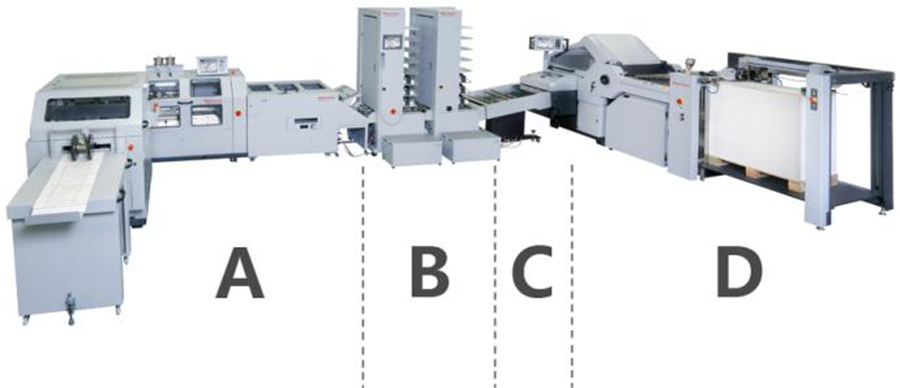

FoldLiner

Foldliner's extension device as StitchLiner 6000 is a "one -stop" Saddle Stitch System. Printed paper can directly produce the finished product through Foldliner. Without excess processing operations and tedious processes, the entire process can complete all production tasks in only 2 people.

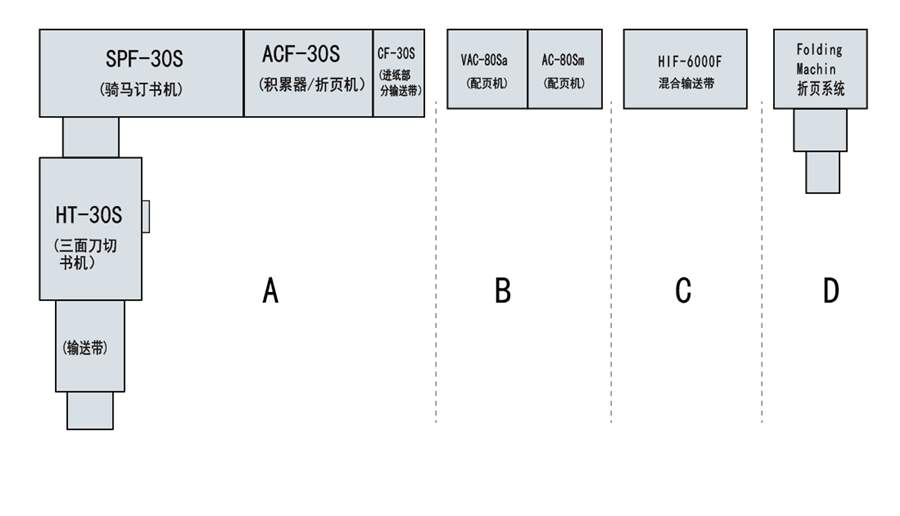

A + B = StitchLiner 6000

D = Horizon folding system

A + C + D = FoldLiner

A + B + C + D = FoldLiner Hybird System

The most significant feature of Horizon's equipment is that they can perform various flexible combinations like "Transformers". The purpose is to customize the most compatible equipment combination of actual production according to production needs, so as to meet customers' various production needs.

The folding system configured by the Foldliner can complete 8 Page. After entering the Saddle Stitch part, 16 Page can be completed. At the same time, because the CF-30S cover to the paper device can be added. The CF-30S cover can complete up to 20 pages of Saddle Stitch after the paper device. If there are additional requirements for the finished page number, you only need to add a pages. After upgrading to FOLDLINER HYBIRD SYSTEAM, the VAC -80S distribution device can be completed to complete the distribution function, thereby increasing the number of page numbers of the final finished product.

FoldLiner Hybird System

The StitchLiner 6000 is configured, so it is equivalent to the "A + B" combination mentioned in the previous article. If long -version processing needs to be performed, the combination of " + C + D" is needed. By configured the perfect upgrade from the StitchLiner Hybird System from the StitchLiner Hybird System.

The biggest advantage of Foldlineer Hybird System is that it can complete the Saddle Stitch processing order with more than 30,000 volumes. Compared to the StitchLiner 6000 suitable for the short version and short version, the Foldliner Hybird System can be processed with both Saddle Stitch and the long version of Saddle Stitch. Production model.

In addition to the long version of production, the folding system in Foldliner can be replaced by the HIF-6000 connection device to the gorgeous upgrade of the traditional Saddle Stitch to the gorgeous upgrade of the traditional Saddle Stitch to digital Saddle Stitch! It should be noted here that because the original folding system was replaced with the use of the roll paper processing system, at this time, Foldlineer Hybird also transformed into a StitchLiner 6000 Digital Hybird System.

Workers must first benefit their tools, and promote the comprehensive development of its equipment from the perspective of users. To achieve a multi -machine, multi -machine interaction, and through the flexible combination of various types of equipment to meet more diverse production needs. At the same time, when we integrate the waste of time with the cost with costs, we can find that these inconspicuous "small things" have been affecting the overall benefits of the enterprise. Horizon expects to help customers save every penny in the production process. Only by reasonable use of resources and planned production with planning can construct a "healthy" enterprise.